Vactan Rust Converter

£20.87 – £236.34 inc. VAT

VACTAN neutralises the corrosion process and protects metal surfaces by forming a film with low permeability to water vapour. One litre of VACTAN can treat up to 8-9 square meters of surface.

VACTAN neutralises the corrosion process and protects metal surfaces by forming a film with low permeability to water vapour. One litre of VACTAN can treat up to 8-9 square meters of surface.

- Self Priming

- Minimal Surface Preparation

- Easy to apply

VACTAN Rust converter is complex moisture of a vinyl acrylic copolymer and tannic acid for the treatment of corroded steel and iron surfaces.

VACTAN neutralises the corrosion process by converting the rust into a blue-black Metallo-organic complex which passivates the surface. It then further protects the surface by forming a film with low permeability to water vapour and oxygen. VACTAN Is self-priming but for long term protection, it is advisable to overcoat with suitable water or solvent-based mid coat or topcoat.

For use on all rusty steel and iron surfaces including:

- boat keels

- cars

- car chassis

- garden furniture

- engines,

- car parts

- machinery

- tractors

- many more…

Usage/dilutions:

One litre of VACTAN can treat up to 8-9 square meters of surface

Application:

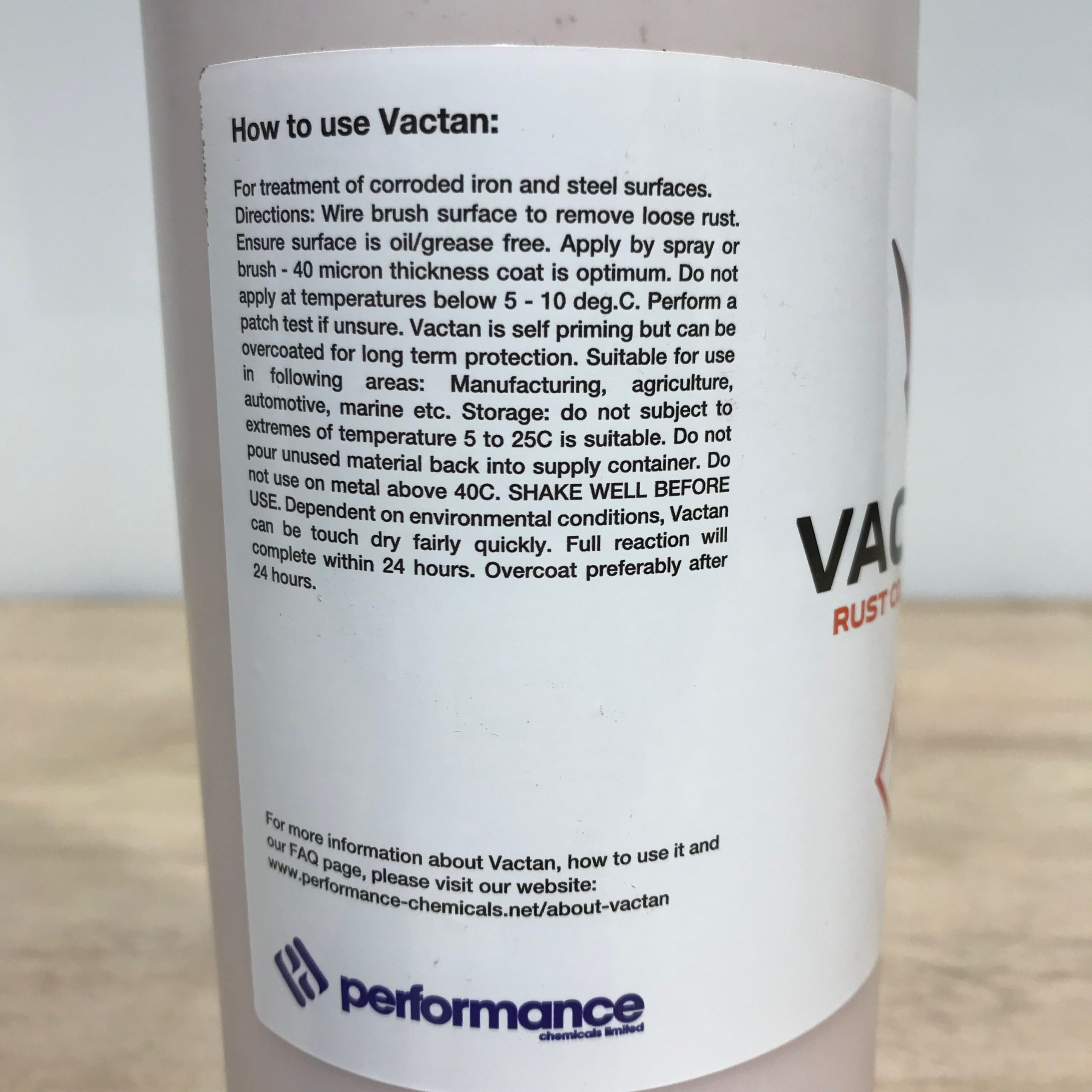

Surfaces should be wire brushed to remove loose rust and it is preferable to remove soluble salts by washing with water as they inhibit the conversion process. Surfaces should also be oil and grease-free.

VACTAN has been designed for application by spray and brush. By airless spray a dry film thickness of up to 60 microns can be achieved without sagging. The addition of further water may be necessary for air assisted spraying. By brush application, a dry film thickness of 40 micros per coat is considered optimum.

VACTAN can be applied over damp surfaces and dries quickly under suitable temperature and humidity conditions. Immediately after use equipment should be washed in water to remove all traces of VACTAN.

DRYING CONDITIONS

Temperature, humidity, air movement and film thickness all affect the time to reach the touch dry stage. Under ideal conditions a 100 micron wet film of VACTAN will be touch dry in approximately 10 minutes at 20°C, whereas at 10°C and with little air movement this time can be as long as 2 hours. VACTAN should not be applied at temperatures below 10°C

VACTAN can be used in the following areas:

- Manufacturing

- Agriculture

- Automotive

- Road Haulage

- Marine

- Heavy engineering

- Building and construction

- DIY

VACTAN is non flammable and can be regarded as essentially non hazardous under normal use. During use gloves should be worn as VACTAN will stain the skin. Stains can be removed by first washing with diluted bleach then plenty of soap and water.

VACTAN should NOT be swallowed. If swallowed seek medical advice immediately.

WE ADVISE USERS OF THIS PRODUCT TO WEAR SAFETY GOGGLES, GLOVES AND SKIN SHOULD BE FULLY COVERED. CAREFULLY READ ALL APPLICATION AND SAFETY INSTRUCTION BEFORE USING

Ingestion: DO NOT induce vomiting, drink 1-2 glasses of water, seek medical attention

Skin Contact: Wash off immediately with plenty of soap and water, Remove

contaminated clothing, flush skin with running water. Seek medical attention if irritation or symptoms persist

Eye Contact: Rinse continuously with water for at least 15 minutes, holding the

eyelids open. Seek medical attention. If can be done easily done

remove contact lenses.

Spills/leaks: Absorb on inert absorbent and transfer to a container.

Prevent spillage from entering natural waters/land drains.

FIRE: Use water fog or fine water spray. Emergency workers to wear full protective clothing including breathing apparatus.

| Weight | N/A |

|---|---|

| Size | 1 Litre, 12x 1 litres, 4 x 1 litres, 6×1 litres |